Minimal Contamination

Scalability

Shorter Processing Time

All models offer the same minimal contamination, ease of maintenance, and scale-up flexibility.

Specifications

Model

Motor kW

Max. Throughput L/h

Explosion Proof Application

External Dimensions (W x D x H mm)

Weight kg

HJP-25001

2.2

6

φ0.1

N/A

180

HJP-25008

7.5

52

φ0.12

Option

1,215×826×1,258

790

HJP-17011

67

φ0.15

HJP-25080

HJP-16140

HJP-10180

75

441

727

1,056

φ0.35

φ0.50

φ0.48

(Dual chamber)

Option

1,330 × 3,150 × 1,900

5,700

Solves problems that commonly occur when homogenizing particles.

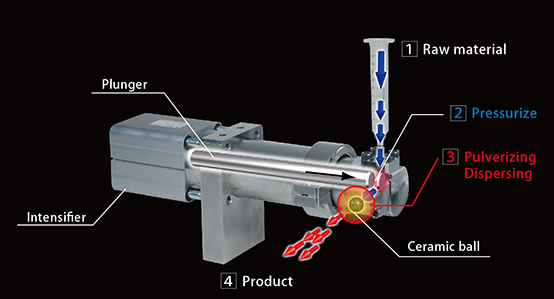

Processing or homogenizing particles to nano-level size can improve their efficacy. Homogenization of particles refers to the process of reducing the average diameter of a material's particles uniformly.

Dispersion

Emulsification

Reduce the size of droplets in liquid.

Pulverization

Crush the primary particles.

Exfoliation

Peel off the layered material.

Want to know more? Sample testing is available in our Stuttgart, Germany lab.

Or, talk to an expert about Star Burst's full capabilities.

Electronics

Battery materials, Oxides, Magnetic materials, Capacitors, CMP slurry

Cosmetics

Pharmaceuticals

Pigments

Toner, Color filters, Printing inks, Paints

Chemicals

Resins, Plastics, polymers, Waxes, Fats, and Oils

Food

Aroma chemicals, Calcium, Antioxidants, Food additives, Functional beverages

Example: Carbon Nanotube 0.1 wt%

Carbon nanotube can be exfoliated by high shear force of high-speed water jetting.

Number of passes: 20

Before:

17 μm

Always precipitated

Pressure: 200 MPa

After:

0.15 μm

Highly stabilized

New Technology Center/Assembly Plant for Star Burst

New production facility for the production of Star Burst.

Ideal for the R&D of super fine particles and emulsions. This model is suitable for research and development in the nano-field.

Ideal for the R&D of super fine particles and emulsions. This model is suitable for research and development in the nano-field.